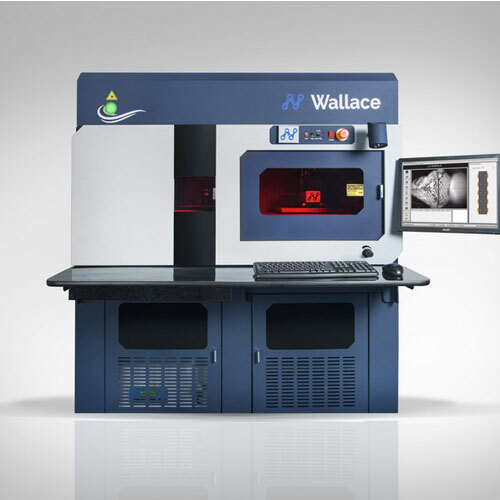

General Features :

- Superior pulse to pulse stability, with inbuilt Peak Power Regulation, imparts high safety in the cutting process.

- Field-proven, long-lasting Optical Coating and Laser Diode Module

- Smart Interlock system guarantees the safe and smooth running of the machine

- Highly engineered and precisely sealed Laser Resonator that ensures nil deviation in output power caused due to vibration and change in environmental condition

- High quality, long life and maintenance-free motion system

- Granite base offers vibration-free operation

- Excellent surface quality throughout the entire depth of cut

Motorized direct driven 360⁰ batch production fixture for :

- Precise Single Side or Double Side Sawing

- Accurate and precise auto pie sawing from two side or single side sawing

- Smart feature to set Multiple sawing planes for cutting the extra pieces in a single operation

- Slicing of CVD with excellent surface finish

- Batch production fixture for very accurate coring of CVD

- Skin banding option for eliminating the risk of diamond breakage because of internal reflection.

- A compact and robust frame structure

Specifications:

- Laser Source : Q- Switched Wavelength Conversion Nd:YAG Diode Pumped Solid State Laser

- Wavelength : 532 nm

- Transverse Mode : TEM00

- Max Output Power : 20 Watt @ 8 kHz

- Polarization Ratio : 100:1 Linear, Vertical

- Beam Quality(M²) : < 1.2

- Beam Roundness : > 90 %

- Beam Diameter : < 0.7 mm

- Beam Divergence : < 1.8 mrad

- Point Stability : < 20 µrad/⁰C

- Pulse to Pulse Stability : < 2 % RMS

- Average Power Stability : < 3 % over 12 hours

- Cooling System : Refrigerated, Air to Water Cooled

- Supply : 1Ø, 220 VAC 50/60 Hz or 110 VAC 50/60 Hz

- Power Consumption : 2 kW Max.

- Room Temperature : < 30⁰ C

- Humidity : < 70 % RH (Recommended)

- Length x Width x Height : 1370 mm x 1030 mm x 1560 mm (54” x 40.5”x 62”)

- Weight : 720 Kg

Experience unparalleled accuracy with the WALLACE Green Laser Machines beam quality (M2 < 1.2), achieving minimum line widths of 0.01 mm and character sizes as small as 0.2 mm. Its stable output and advanced optics ensure detailed engraving suitable for electronics, precision tools, and fine jewelry applications, delivering consistently clean, clear marks on a variety of substrates.

User-Friendly Operation and Versatile Software SupportThe machine integrates seamlessly into your workflow via USB and supports multiple graphic formats such as DXF, PLT, AI, BMP, and JPG. EzCad control software simplifies the marking process, while compatibility with Windows 7/8/10 brings increased accessibility for operators. The included air cooling and fan system ensure operational stability within a broad range of temperatures and humidity.

Maximum Efficiency with Low Power ConsumptionWith less than 600W power usage and a built-in cooling system, the WALLACE Green Laser Machine excels in energy efficiency. Despite its robust capabilities and 65 kg build, it supports rapid marking speeds up to 7000 mm/s, maximizing productivity without excessive energy demands, making it suitable for continuous use in industrial environments.

FAQs of WALLACE Green Laser Machine:

Q: How does the WALLACE Green Laser Machine ensure high marking accuracy?

A: This machine delivers superior marking precision due to its excellent beam quality (M2 < 1.2) and high stability. It can engrave with a minimum line width of 0.01 mm and a minimum character size of 0.2 mm, ensuring crisp and detailed results. The systems integrated CNC control and EzCad software further enhance repeatability and precision.

Q: What graphic formats are supported by the green laser machine for marking?

A: The machine is compatible with a wide range of graphic formats including DXF, PLT, AI, BMP, JPG, and others. This broad compatibility allows easy import of designs from most vector and raster-based design software, streamlining the marking process.

Q: Where can the WALLACE Green Laser Machine be optimally used?

A: Designed for versatility, the machine is ideal for industrial marking applications across electronics, jewelry, medical devices, and precision tools. Its robust build and operating environment tolerance (0C-40C, 20-80% humidity) make it suitable for production facilities and workshops in India and abroad.

Q: What benefits does the built-in air cooling system offer?

A: The built-in fan and air cooling system maintain optimal temperatures for stable laser performance and long equipment lifespan, even during extended operation. This design negates the need for complex external chillers, reducing maintenance demands and operational costs.

Q: When is it recommended to perform maintenance on the machine?

A: Routine maintenance includes inspecting the air filter and fan system, ensuring software and firmware updates, and regularly checking for dust or debris. Schedule maintenance based on usage frequency, but generally every 612 months is advised for optimal performance.

Q: How energy efficient is the WALLACE Green Laser Machine?

A: Despite its powerful marking capabilities, the machine uses less than 600W of power due to its advanced design and air cooling system. This low consumption allows continuous operation with minimal electricity costs.

Q: What are the main advantages of using a green laser (532 nm) for marking applications?

A: Green lasers operate at 532 nm, a wavelength highly effective for precise marking on materials less responsive to infrared lasers. This means cleaner, higher-contrast marks on substrates like plastics or metals and an expanded application range for industries demanding fine detail.