General Features :

Specifications:

- Laser Source : Nd:YAG Diode Pumped Solid State

- Wavelength : 1064 mm

- Transverse Mode : TEM

- Max Output Power : 24 Watt @ 10kHz

- Beam Polarization : Linear – Vertical

- Cooling System : Refrigerated, Air to Water Cooled

- Supply : 1Ø, 220 VAC 50/60 Hz or 110 VAC 50/60 Hz

- Power Consumption : 2 kW Max.

- Room Temperature : < 30⁰ C

- Humidity : < 70 % RH (Recommended)

- Length x Width x Height : 930mm x 890mm x 1500mm (37” x 35”x 59”)

- Weight : 505 Kg

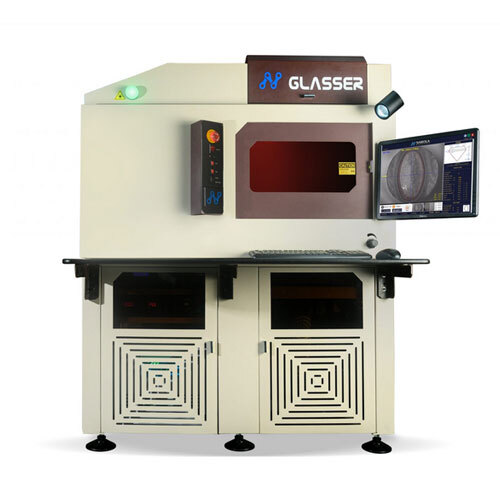

Engineered for demanding applications, the GLASSER IR-Green Laser Machine delivers precision with a minimum line width of 0.01 mm and minimum character size of 0.2 mm. The versatile marking area options and rapid repeat frequency from 20 KHz to 80 KHz make it suitable for intricate designs and serial production. The air-cooled system maintains optimal temperatures (0C - 40C), ensuring consistent performance.

User-Friendly Operation and Broad CompatibilityThe integrated control software, EZCAD, streamlines the marking process for a range of users. The system's USB interface and support for popular graphic file formats (AI, DXF, JPG, BMP, PLT, PNG, etc.) facilitate hassle-free design import and operation. Whether it's for metals, plastics, or ceramics, this laser machine adapts to varied manufacturing requirements.

FAQ's of GLASSER IR-Green Laser Machine:

Q: How does the GLASSER IR-Green Laser Machine ensure high precision during marking operations?

A: The GLASSER IR-Green Laser Machine boasts a beam quality of M2 < 1.2 and achieves a minimum line width of 0.01 mm with accuracy up to 0.01 mm. This precision is further enhanced by its stable repeat frequency range and finely controlled marking speeds, making it ideal for applications that demand detailed and reliable engravings.

Q: What materials are suitable for marking with this laser machine?

A: This versatile laser machine effectively marks on metals, plastics, ceramics, PC, ABS, PVC, and similar substrates. The dual-wavelength capability (1064 nm and 532 nm) allows optimization for different material types, ensuring high-quality marks across various industrial applications.

Q: When is air cooling most effective for this laser's operation?

A: Air cooling is optimal within the specified ambient temperature of 0C to 40C and humidity from 5% to 85% (non-condensing). This ensures stable performance, preventing thermal issues during both short- and long-duration marking campaigns.

Q: Where can the GLASSER IR-Green Laser Machine be integrated within a manufacturing workflow?

A: Thanks to its moderate footprint (800 mm x 650 mm x 1450 mm) and USB connectivity, the laser machine can be incorporated into CNC-driven production lines or standalone workstations in manufacturing facilities, research labs, or workshops handling metal, plastic, or ceramic components.

Q: What is the process for importing designs onto the laser machine?

A: Designs can be imported directly via USB using supported graphic formats such as AI, DXF, BMP, JPG, PNG, PLT, and more. The accompanying EZCAD software provides an intuitive interface for setting up marking parameters and managing the workflow efficiently.

Q: How does using this machine benefit exporters, manufacturers, or suppliers?

A: By employing the GLASSER IR-Green Laser Machine, businesses gain rapid, consistent, and highly accurate marking, which enhances traceability, branding, and product differentiation. Its flexibility and simple operation streamline production, minimize downtime, and support high-volume requirements common to exporting and supply sectors.