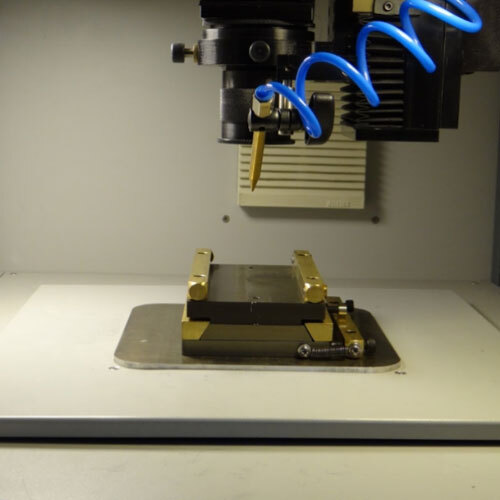

- This is a well-known base fixture fitted on the X-Y axis upon which all the other fixtures are mounted for various applications.

- It has a dovetail base for accurate and quick exchange of other fixtures while performing various operations.

- The Dovetail base bearing design facilitates precise and fast aligning of the Saw plane/cutting line.

Precision Meets VersatilityThe base plate fixture ensures reliable component holding, enabling ultra-precise marking with an accuracy of 0.01 mm. Its robust construction and powder-coated finish provide exceptional corrosion resistance, making it efficient under demanding industrial conditions.

Universal CompatibilityDesigned to fit seamlessly with most laser engraving and marking machines, this fixture supports a wide power range (15W-100W) and allows integration with CNC controls and popular industrial software. The adjustable clamping mechanism accommodates various component shapes and sizes, ensuring broad applicability.

Customizable for Diverse NeedsWith customizable dimensions, marking areas, and color options, the fixture adapts perfectly to specific project or industry requirements. Exported and supplied from India, it meets global standards while offering tailored solutions for manufacturers and suppliers worldwide.

FAQ's of Base Plate Fixture:

Q: How is the base plate fixture installed onto laser marking machines?

A: The fixture is base plate mountable and designed for simple integration with most standard laser marking machines. It utilizes adjustable mechanical clamps to securely hold components, ensuring stability throughout the marking process.

Q: What are the primary benefits of using this high-grade steel fixture for laser engraving applications?

A: The high-grade steel structure, combined with a powder-coated surface, offers outstanding durability, corrosion resistance, and accuracy. This results in consistent, precise markings on components, improving operational efficiency and product quality.

Q: When should I consider customizing the dimensions or marking area of the fixture?

A: Customization is recommended if your marking requirements involve non-standard components or larger marking areas. The manufacturer can tailor dimensions (such as 250 mm x 250 mm x 50 mm or marking areas up to 200 x 200 mm) to precisely match your application.

Q: Where can this base plate fixture be used?

A: It is ideal for use in industrial settings where precision marking or engraving is essential-such as manufacturing plants or workshops. The fixture supports a wide temperature range (0C to 45C) and is suitable for both small-scale and large-scale marking operations.

Q: What is the process for holding and marking components with this fixture?

A: The fixture incorporates adjustable mechanical clamps that firmly secure the component in place. Once secured, the laser marking process proceeds, utilizing CNC controls if needed, to achieve highly accurate results with minimal repositioning.

Q: How does the air-cooled system contribute to the fixture's performance?

A: The integrated air-cooling mode dissipates heat effectively during extended marking sessions, ensuring consistent performance and preventing damage to both the fixture and the workpiece.