Why Choose Us?

At Narola Machines, we focus on innovation and quality to bring you the best in laser cutting solutions. Our Fiber Laser Cutting Machine combines performance, reliability, and affordability, ensuring that you can meet your production demands with confidence. We provide excellent after-sales support and training to help you maximize the benefits of your investment.

- High Cutting Precision: Achieve razor-sharp cuts and minimal material wastage with clean, burr-free edges.

- Efficient Operation: Intelligent control system for high-speed processing and low energy consumption.

- Wide Material Compatibility: Cuts stainless steel, carbon steel, and non ferrous metals effortlessly.

- Advanced Motion System: CNC control and servo motors ensure smooth, fast, and accurate cuts.

- Durability Low Maintenance: Top-quality components for long-lasting performance.

- User-Friendly Interface: Intuitive remote control for easy setup and operation.

Key Benefits

- Optimal airflow for improved performance.

- Clear visibility of the workspace for safety.

- Easy maintenance and high flexibility for various metals.

Technical Parameters

NMC-1500

- Working Area : 3000 mm × 1500 mm

- Laser Type : Fiber Laser

- Laser Power : 1.5 Kw

- X-Axis Travel : 1505 mm

- Y-Axis Travel : 3005 mm

- Z-Axis Travel : 200 mm

- Max Positioning Speed (X-Y Axis) : 50 m/min

- Positioning Accuracy : ±0.05 mm

- Repositioning Accuracy : ±0.03 mm

- Max Cutting Speed : 60-70 m/min

- Cutting Thickness : 0.1-25 mm

- Voltage : 380 ± 10% VAC, 3 Ø, 50/60 Hz

- Auxiliary Gas : O₂ / Air / N₂

- Max Carrying Weight : 800 kg

- Overall Dimension : 4800 mm × 2250 mm × 1800 mm

NMC-2000

- Working Area : 3000 mm × 1500 mm

- Laser Type : Fiber Laser

- Laser Power : 2 Kw

- X-Axis Travel : 1505 mm

- Y-Axis Travel : 3005 mm

- Z-Axis Travel : 200 mm

- Max Positioning Speed (X-Y Axis) : 50 m/min

- Positioning Accuracy : ±0.05 mm

- Repositioning Accuracy : ±0.03 mm

- Max Cutting Speed : 60-70 m/min

- Cutting Thickness : 0.1-25 mm

- Voltage : 380 ± 10% VAC, 3 Ø, 50/60 Hz

- Auxiliary Gas : O₂ / Air / N₂

- Max Carrying Weight : 800 kg

- Overall Dimension : 4800 mm × 2250 mm × 1800 mm

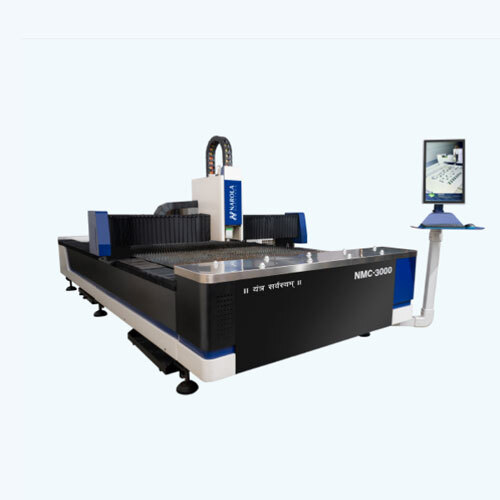

NMC-3000

- Working Area : 3000 mm × 1500 mm

- Laser Type : Fiber Laser

- Laser Power : 3 Kw

- X-Axis Travel : 1505 mm

- Y-Axis Travel : 3005 mm

- Z-Axis Travel : 200 mm

- Max Positioning Speed (X-Y Axis) : 50 m/min

- Positioning Accuracy : ±0.05 mm

- Repositioning Accuracy : ±0.03 mm

- Max Cutting Speed : 60-70 m/min

- Cutting Thickness : 0.1-25 mm

- Voltage : 380 ± 10% VAC, 3 Ø, 50/60 Hz

- Auxiliary Gas : O₂ / Air / N₂

- Max Carrying Weight : 800 kg

- Overall Dimension : 4800 mm × 2250 mm × 1800 mm

Precision and ReliabilityEquipped with a CNC controller, auto-focus laser head, and dual rack-and-pinion drive powered by servo motors, this machine ensures unmatched cutting precision. The reinforced welded steel frame minimizes vibrations, while repeat positioning accuracy of 0.02 mm and a maximum acceleration of 1.2G enable high-speed, accurate operations across demanding production schedules.

User-Friendly and Safe OperationThe machine features a responsive touch screen HMI for intuitive control and monitoring. Integrated safety systems include emergency stop functions and laser safety protection circuitry, ensuring operator safety at all times. Windows OS compatibility and support for multiple graphic formats streamline workflow integration.

Versatile Applications and ProductivityIdeal for industries such as automotive, electrical enclosures, signage, and kitchenware, the laser can cut various metals up to 20 mm thick. With optional rotary attachments for tubes and automatic loaders/unloaders, users benefit from enhanced productivity and flexible customization. Continuous 24/7 operation is supported to meet high-volume manufacturing needs.

FAQ's of Open-Frame Fiber Laser Cutting Machine:

Q: How does the auto-focus laser cutting head improve the cutting process?

A: The auto-focus laser cutting head automatically adjusts the focal length based on material thickness, ensuring optimal beam quality, faster processing times, and consistent, high-precision cuts.

Q: What types of materials can be cut with this fiber laser machine?

A: This fiber laser cutting machine efficiently processes carbon steel, stainless steel, aluminum, brass, and copper, supporting sheet thicknesses up to 20 mm depending on the selected power and material type.

Q: When is installation service provided for the machine?

A: On-site installation service is available upon purchase, with scheduling coordinated to suit customer availability and ensure proper setup, calibration, and user training.

Q: Where is the machine typically installed or used?

A: The machine is suitable for manufacturing facilities, workshops, and industrial sites requiring precision sheet metal processing such as automotive parts, electrical enclosures, kitchenware, and signage manufacturing.

Q: What safety features are integrated in this laser cutting machine?

A: Safety is ensured via emergency stop controls and comprehensive laser safety protection circuitry, minimizing risks during operation and adheres to industrial safety standards.

Q: How does the open-frame design benefit users during operation?

A: The open-frame construction provides easy access for material loading, unloading, maintenance, and customization, streamlining workflows and reducing downtime.

Q: What software and graphic formats are compatible with the control system?

A: The CNC controller supports CypCut, LaserCut, or equivalent software compatible with Windows OS, and accepts AI, BMP, DST, DWG, DXF, DXP, LAS, and PLT graphic files for seamless integration with design processes.